| HEMPOLOGY.ORG: THE STUDY OF HEMP

|

|||

|

|

||

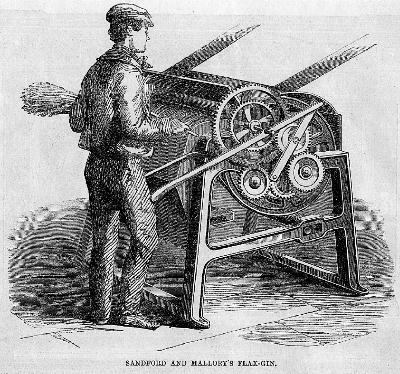

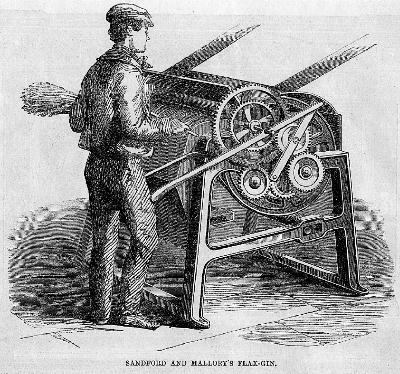

SANDFORD AND MALLORY'S FLAX-GIN.

Although of a very unpretending appearance, the flax-gin of America may claim a value for industrial usefulness greater than some of the more attractive and highly-finished objects of the exhibition, especially as the supply of textile materials to the spinning-mills of England becomes at this time a question of solicitude.

In America, where large quantities of flax and hemp are grown, any process which abridges the labour of freeing fibre from ligneous stalk is a matter of great moment, in consequence of the scarcity of manual help; and to overcome this difficulty the "Sandford" machine, belonging to Sandford and Mallory, was designed, and seems to have worked with satisfaction in that country. Textile materials like flax and hemp are generally submitted to a process of retting, that is to say, steeping the plants in water or exposing them on the surface of corn stubble until the gummy material is partly dissolved, by which means the fibre becomes separable from the stalk. The first process is called water-retting, the second dew-retting. Great improvements of later years have been made in water-retting by substituting steam or hot water instead of field-steeping. It is obvious that flax-cultivators, especially small ones, do not always follow the right way in the process; consequently the value of the yield is greatly diminished. This machine expeditiously takes off the extraneous vegetable matter from the fibre as it arrives from the field in a green state, or it also performs the duty of a scutching-machine, and dispenses with handbreaks and swingles.

The operation of the machine is simple enough. In its centre, on a cross-shaft, there are two iron rings joined to radial arms; on these rings are mounted angular bars in a line with the shaft, their face being sharp, but of so obtuse an angle that, although they serve as scrapers, they will not cut the fibre. Between each bar another similar bar is placed, having a portion of its outer angle cut into fine but obtuse teeth so as to penetrate between the fibres, and also to keep the strake of flax or hemp in a proper direction.

Behind the cylinder described there are a pair

of endless belts passing over rollers and pressing against the

bars of the principal cylinder; consequently they take a curvature

representing a segment of the cylinder. At the same distance apart,

and fastened to and across the endless belts, similar bars to

those on the cylinder are firmly fixed; consequently, when the

fibre is put into the machine it passes between the two sets of

scraping-bars, and is kept in a continuous state of changing curvature

by the successive pressure of the bars, which pass over every

part of the surfaces of the fibre with great velocity. The feed

is performed by a fluted metal roller, which has pressed upon

it with considerable force another roller covered with indiarubber.

A back or reverse motion of the feed-rollers returns the fibre.

When half the length is cleaned the other end of each strake is

then operated upon. When the machine works upon green materials

a stream of water is run through it to wash away the pulpy vegetable

matter which is separated from the fibres.